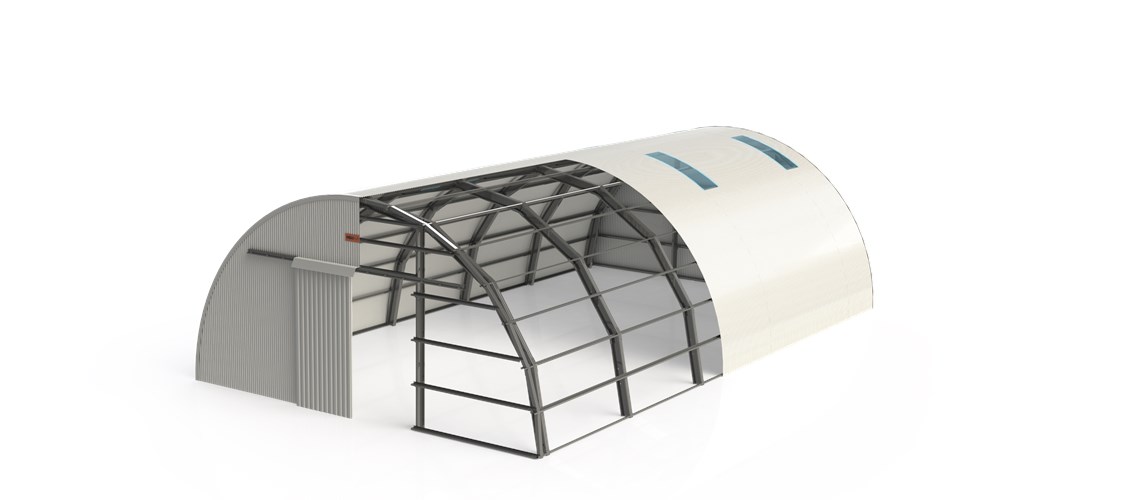

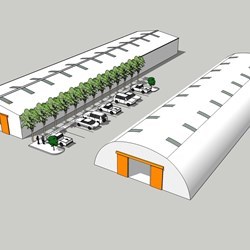

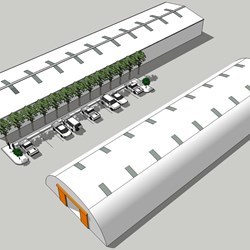

Galpão Express : Frisomat Omega+

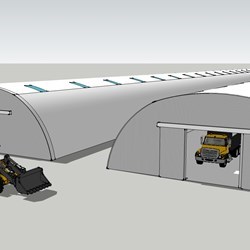

The Frisomat Omega is a 100% Brazilian produced warehouse, made with innovative technology to reach European quality norms. This and the smart modular design, makes this sturdy round roofed barn immediate available, easy to transport, easy to mount, easy to expand and possible to displace and reuse. Matsul sells and builds hangars in RS and the south of Brazil.

features

Omega : an arched steel hangar with elegant lines at an unbeatable price. Although 30 years in the Frisomat portfolio, recently upgraded and more kicking than ever!

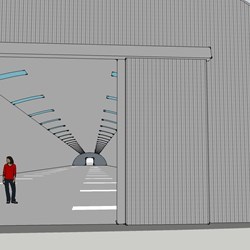

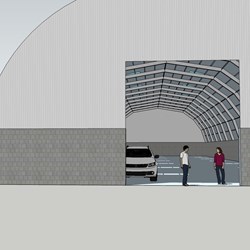

The standard RAL 9003 white color has good heat reflective properties. A 2 foiled gate and translucent sheets in the roof for daylight are standard. The optional extra wide sliding doors offer you the ideal solution for its initial purpose : hangaring small airplanes and helicopters. You will find many of Frisomat’s Omega’s on airfields all over the world. Do you have an Embraer Ipanéma on your fazenda ? This building protects it from the strongest winds, extend it a bit and there’ll be room in the back for your harvester too !

Actually, up till now, Frisomat produced and erected more than 10.000 Omega’s ! We dare to say that we know what we’re talking about…

immediate available

All cladding, panels, columns are pattern made in our factory in Monte Mor, SP along a limited number of standard sizes. Parts are in stock or can be rapidly produced. The lightweight, yet strong structure can be erected on almost every soil, using a simple or prefabricated foundation. This and the fact that the parts just need to be bolted together on the erection site, makes extremely short delivery times possible. Compact and lightweight parts, make transport and manipulation easy, with a budget-friendly result.

applications

Originally designed to hangar airplanes, nowadays they fulfil many needs: garage, storage, workshops, warehouse, temporary shelters, sports hall… and when equipped with, or built on top of a flood wall, perfect to store bulk products, like grains, fertilizer, salt, wood pellets and so on… Do you need a workshop or a warehouse? Temporary shelter on a construction site? Thanks to the form and concept, an Omega can simply be disassembled and reused on an other site.

conform ABNT norms

The cold rolled steel is all galvanized which guarantees longevity, the structure is light but rigid. Calculated to ABNT norms it will survive winds up to 180 km/h (50 m/s wind region V in south Brazil) To reach this, we adapt steel thickness and column pitch, when needed. Thence, when asking us a quote, we will always consider the exact location and rugosity of the construction site, guaranteeing your harvester, or your biplane to survive the fiercest storm.

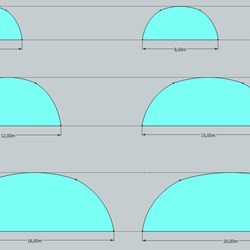

dimensions

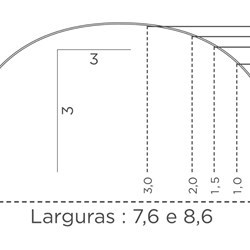

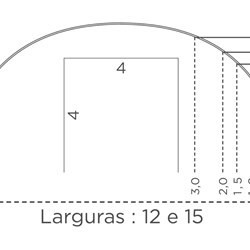

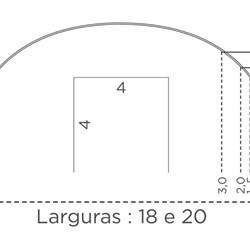

The length starts at 10 or 13m and is unlimited, the span width is linked with the height :

- Span width 7,6 and 8,6m : height is 3,8m

- Span width 12 and 15m : height is 5,5m

- Span width 18 and 20m : height is 6,6m

At all times the Omega can be expanded by adding more segments. This is easy because our system is modular and just bolted together.

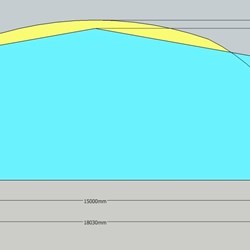

What is an Omega+ ?

The omega+ is the latest development of this concept. This applies for the 18 and 20m spans. The span segments are straight and short, made from cold formed galvanized steel. All couplings are hot dip galvanized. Apart from being better protected, the parts are easy to stack and transport. This results in a cleaner, lighter, more budget-friendly design.